Tailings

Mining dams pose a substantial risk, and residue management clearly needs to change. Alfa Laval is leading that transformation. The robust design and large capacity of our solid-bowl decanter centrifuges have proven the perfect solution for safe and secure dewatering of mining tailings. The small footprint substantially reduces installation space. The consistency of the solids fraction is perfect for co-disposal or dry stacking. And you recover large volumes of water for reuse.

Ensuring a fast, continuous process for safe, clean and efficient solid-liquid separation

- High capacity and separation efficiency with optimal solids dryness

- Long working life

- Designed for high-density sludge

- Compact design and small installation area

- Easy to scale-up capacities from test results

Как работи технологията

Декантерните центрофуги Alfa Laval P2 и P3 са специално проектирани да сепарират суспензии от минерална руда, както и за сепарирането на хвост на твърда фракция и течна фракция. Сепарирането се извършва в хоризонтален барабан, оборудван с транспортиращ шнек. Захранващата суспензия се подава в барабана през стационарна входна тръба и след това плавно се ускорява в зоната за захранване. Центробежни сили до 3500 G отделят твърдите частици от течността и твърдите частици се натрупват върху вътрешната повърхност на барабана.

Шнекът се върти в същата посока като барабана, но на различни обороти. Това дава аксиален тласък на твърдите частици и шнекът пренася тези частици към коничния край на барабана. Твърдите частици напускат барабана през отворите за изпускане на твърди частици в корпуса, докато избистрената течност напуска барабана, като протича през регулируемите плочи или напорни тръби в корпуса.

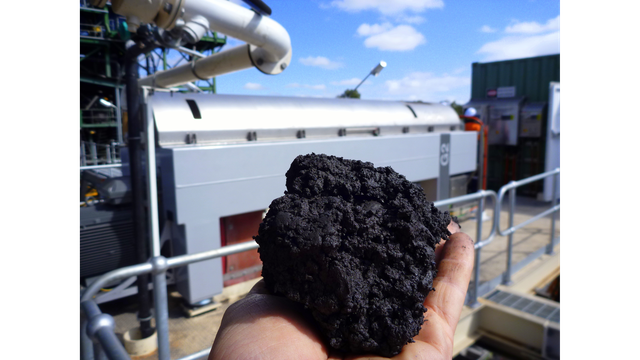

Tailing dewatering

Breaking new ground in mining and minerals

Alfa Laval’s solid-bowl decanter centrifuges are the perfect choice for a wide range of solid-liquid separation duties in mining and mineral applications. They can replace or complement existing solutions and help boost capacity, reduce tailings volumes, save space and increase the recovery of water, chemicals and minerals. Above all, the decanter eliminates the need for tailing damns which enhance the intrinsic safety of your operation.

Optimizing your solid-liquid separation processes is a straightforward way to cut operating and investment costs while minimizing your company’s environmental impact. In many cases you can raise plant profitability by simply adding Alfa Laval’s solid-bowl decanter centrifuges to traditional separation systems such as thickeners, sedimentation basins, filters, etc, or replace the old system altogether.

Rix’s Creek Coal Preparation Plant, Australia

The Rix’s Creek coal mining operation, part of the Bloomfield Group, set out to improve its onsite coal tailings management as part of its sustainability strategy. This is done in order to reduce water and energy consumption and minimize the surface footprint of waste handling processes.

Mature fine tailings, Canada

More than 30 Alfa Laval decanter centrifuges have been installed at three different tailings treatment sites in Canada. The decanters have proven to be an outstandingly efficient solution for large-scale dewatering of tailings. They efficiently remove the finest particles that conventional solids control equipment is unable to deal with.

Eti Maden, Turkey

The world’s largest borate mining company is Eti Maden in Turkey. There they use an array of fully protected Alfa Laval decanter centrifuges to separate tailings from a saturated borate solution. The company is very pleased with the long track record of reliable operation, low maintenance costs and strong local service support from Alfa Laval.

Solid Bowl Centrifuge makes Tailings dam redundant

Solid Bowl Centrifuges technology is about to transform tailings storage in ponded water in the mining industry radically. During the webinar, a number of alternative technologies for treatment and dewatering of tailings will be evaluated from perspectives of productivity, risk management and environmental impact.

Управление на хвоста

Посрещнете предизвикателството за обезводняване на хвоста с декантерните центрофуги на Alfa Laval. Те предлагат рентабилно, устойчиво и преди всичко безопасно решение за управление на хвоста. Изтеглете брошурата, за да прочетете повече за нашите по-чисти, по-ефективни и по-безопасни системи за сепариране на твърда от течна фракция.

Make sustainable development happen!

If you are looking for ways to increase the efficiency of your tailings management and make a meaningful contribution to the global sustainable development goals, contact Alfa Laval today to learn more about our proven and cost efficient solutions.