Benefits of using Alfacond in the sugar process

Remaining profitable in the highly-competitive sugar market calls for sustainable solutions that reduce energy, water and maintenance costs while boosting yield.

DATE 2023-11-28Alfacond Customer Story

For PT. Permata Dunia Sukses Utama, Alfa Laval AlfaCond plate condensers deliver

‘With Alfa Laval plate condensers, we recover the condensed vapour for reuse in our melting station, and we can easily measure the benefits in terms of energy savings and reduction on our fresh-water consumption declares General Manager Mr. Choo Chun

‘“We maintain the condensers easily and appreciated with support of local Alfa Laval technical team.”

Major force in Indonesian agriculture and industry PT. Permata Dunia Sukses Utama (PT. PDSU) which is one of the biggest sugar refinery plant in Indonesia is converting raw sugar to white crystal sugar for industrial use. The company was established in 2003 with current rated melting capacity of 1800 TPD.

PT. PDSU is a member of Indonesia Refined Sugar Association (AGRI) and currently use AlfaCond units as sugar evaporator condensers and vacuum pans condensers.

Benefits of using AlfaCond in the sugar process

Low sugar prices worldwide, exert big pressure on all sugar producers to maximise energy savings and to ensure uninterrupted production during the high-pressure, time-limited harvest and subsequent processing campaign.

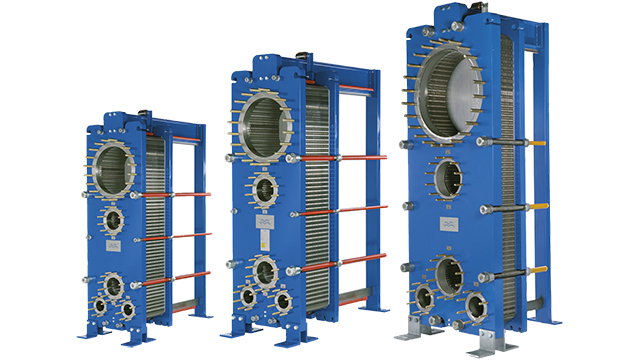

Alfa Laval plate heat exchanger units are widely recognized as state-of-the-art in terms of heat transfer efficiency, enabling the user to achieve significant energy savings.

The reliability of all equipment in the plant, as well as the servicing and maintenance costs are crucial for the profitability of the user’s operations.

This is present in the form of Alfa Laval plate condensers. They feature higher thermal efficiency and better flow geometry than any conventional alternative.

Together, these also lead to benefits that include compact size, better heat recovery and increased productivity.

Product Benefits

AlfaCond is a plate condenser designed for condensation under vacuum. AlfaCond is based on Alfa Laval’s semi-welded technology. Vapour condenses in the welded channel while the cooling medium passes through the gasketed channel

Features and benefits

• Optional sub-cooling of condensate and non-condensable gases

• Flexible configuration

• Heat transfer area can be modified

• Cooling media doesn’t mix with condensed media

• Easy to install – compact design

• High serviceability

• Easy to open for inspection and cleaning and easy to clean by CIP