SB Carlsberg Flask

Alfa Laval SB Carlsberg Flask has been developed specifically for aseptic yeast management in breweries. It is used for sterilizing wort and propagating pure yeast culture on a laboratory scale for use in yeast propagation plants in breweries (as well as in the dairy, food and beverage industries). The flask is made of materials that meet stringent sanitary requirements and can be easily autoclaved.

Ideal sterile environment for yeast cultivation

- Sterility assured by all-in one design solution

- Eliminates unwanted agents that can influence cultures thanks to hygienic, easy to clean configuration

- Safe and sterile transfer assured by integrated components and system approach

- Easy to move to location required

- Robust construction ensures yeast integrity

Каталог „На една ръка разстояние“

Продуктовият каталог „На една ръка разстояние“ за хигиенно оборудване включва листовки за продукти, връзки към анимации, брошури и списъци за поръчки.

Портал за компютърно проектиране (CAD)

Порталът CAD на Alfa Laval е основна платформа за изтегляне на подробна информация за продуктите, 2D чертежи, както и 3D модели на продукти.

Услуги

Нашата специално изградена глобална мрежа от сервизни центрове ви осигурява с резервни части и експертиза, независимо къде се намирате и кога имате нужда от тях. Като ви гарантираме по-продължителен период на безотказна работа, достъпност и оптимизация, ние ще ви помогнем да работите спокойно и да увеличите максимално възвращаемостта на своите инвестиции. Ще ви помогнем да интегрирате нашите сервизни услуги чрез Споразумение за сервизни услуги на Alfa Laval за предсказуема и безпроблемна работа на оборудването.

Научете повече за нашето предложение за обслужване Отстраняване на неизправности

Резервни части Техническа поддръжка

Търсене на сериен номер Сертификация

Моля, свържете се с нас за всякакви запитвания или въпроси.

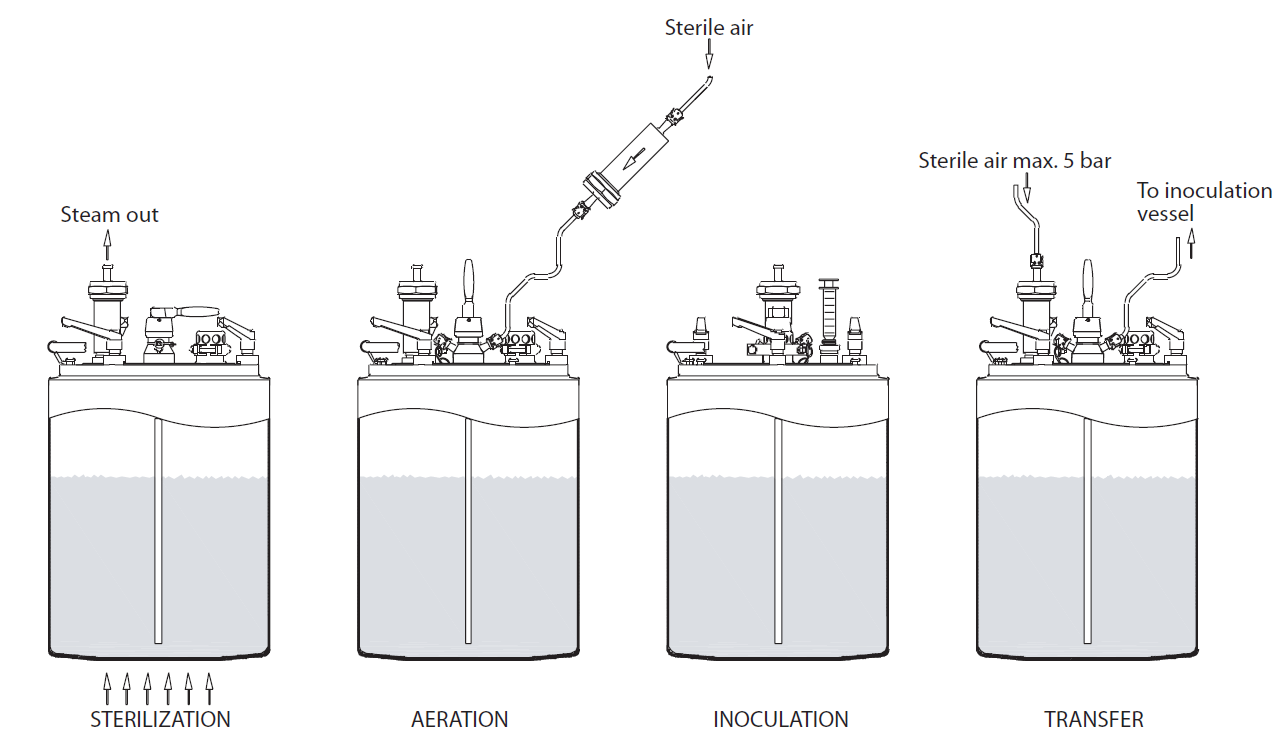

How it works

When the wort is well aerated, the yeast culture is introduced aseptically through the membrane fitting using a 150-200 ml syringe. You can also transfer dry yeast culture to the flask through the empty filter housing. If you need larger quantities of yeast, the lid can be dismantled and the culture poured into the flask. This procedure, however, requires a sterile environment and the highest degree of precaution.

The transfer of pure yeast culture into the propagation plant should take place at the “high kräussend” stage under aseptic conditions and requires a sterile air supply to the breathing filter. Recommended sterile air supply during inoculation into yeast propagation plant is 2 bar and must not exceed 5 bar (72.5 psi) at any time. The yeast culture can be pressed from the flask into the inoculator once the membrane sample valve on the lid of the Carlsberg Flask has been connected to a sample device on the receiving vessel (the inoculator).

The connecting hose, membrane sample valve and all other connections must be thoroughly sterilized with either alcohol or steam before transfer. Between operations, the valve can be sealed with alcohol, which can then be flushed out with sterile air prior to use.

When you have made the connection and you are ready to inoculate, we recommend first opening the sterile air supply, then the membrane sample valve on top of the flask and finally the sample device on the inoculator.

When the culture has been transferred (indicated by a bubbling noise in the inoculator), we recommend continuing with the air supply for another couple of minutes to make sure that all of the yeast culture has been transferred.

Finally, the sample device on the receiving vessel and the membrane sample valve on the Alfa Laval SB Carlsberg Flask can be closed, effectively closing offer the air supply.

After use, the flask needs to be taken apart and cleaned manually with normal detergents.

The Alfa Laval SB Carlsberg Flask consists of a cylindrical container with a flat bottom and top cover equipped with breathing filters, a membrane sampling valve for aeration and product transfer, and a micro sample port for aseptic introduction of pure yeast culture. During the transfer of pure yeast culture from the Alfa Laval SB Carlsberg Flask to the yeast propagation plant, it is important that all hose tails are safely fastened with hose clips.

The flask is filled with wort to the net capacity (approximately 80% of the total volume) sterilized using an autoclave, a gas burner or an electric hotplate. The flask is then placed in a refrigerator or a cold room to cool the wort to the desired working temperature. The cold wort is aerated through the membrane sampling valve connected to the aeration lance.

Yeast culture can be introduced aseptically through the membrane fitting with a syringe, or dry yeast culture can be transferred to the flask through the empty filter housing.

The breathing filter can remain attached to the flask during sterilization. However, if the breathing filter has been sterilized separately, it is important to reattach it while steam is still evaporating from the flask (at the end phase of the wort sterilization) so that the filter connection is also sterilized. The empty filter housing can be used as funnel for transferring pure dry yeast culture to the flask.

The cold wort is then aerated through the membrane sampling valve connected to the aeration lance. It is important to use sterile air. For safety reasons, it is also recommended to feed the wort through a filter mounted ahead of the membrane sampling valve .

Air supply and flow should be moderate to avoid foaming. It is important that foam does not come into contact with the breathing filter because it may block and damage the filter.

The easiest way to determine the right conditions for the air supply as well as the time needed for aeration (less than 10 minutes) is to test with the flask lid open. Note that you cannot use the yeast culture from these tests.

Part of a broad valve range

Alfa Laval offers a comprehensive range of valves intended for hygienic applications in various industries including dairy, food, beverage,home care, personal care, biotechnology and pharmaceuticals:

Може би се интересувате също от...

Десет топ съвета – вентили

Тук ще намерите съвети и видеоматериали с процедури за обслужване, за да видите как да поддържате хигиенните вентили в оптимално състояние

За хранително-вкусовата промишленост

Хигиенното оборудване на Alfa Laval комбинира висока производителност и внимателна обработка, за да запази деликатните хранителни съставки. Поддържа синхрон с тенденциите в хранително-вкусовата промишленост и решава четири основни задачи: доставяне на хранителни продукти на потребителите на конкурентна цена, извличане на максимума от суровините, намаляване на отпадъците и емисиите и доставяне на безопасни и хигиенични хранителни продукти.

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Анимации

Посетете сайта за анимации и разгледайте отвътре даден продукт, за да видите и разберете как функционира.